Breathtaking growth for a new mask manufacturer

Meeting the demand while managing energy costs

The last five months have been life-changing for all of us. But not many businesses have been on a journey quite like the team at Breathe Medical Manufacturing in Kelowna.

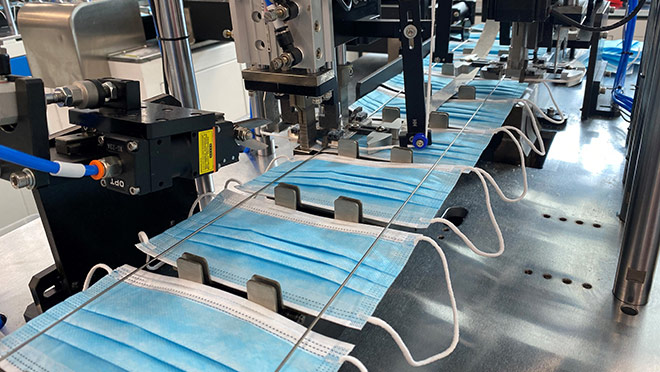

Incorporated on March 9, Breathe's original goal was to produce high quality surgical masks, with the possibility of also producing heavy-duty N95 masks in the future.

"We originally took 30,000 square feet and even though we've only been actively building here for about two months, we're just about ready to fire everything up," says Warren Jones, President of Breathe. "We ordered two batches of six machines and we're just dialing them in and tweaking them."

Even before production starts, the pandemic has required Breathe to grow, adds Warren. "We've taken another 30,000 square feet in the same building and we're going to be putting in 24 N95 machines, along with another 12 for surgical masks. Our projected monthly production will be around 80 million surgical masks and 35 to 40 million N95 masks. So we're currently looking at 48 machines in total."

When you're making something as critical as medical masks in the middle of a pandemic, volume isn't everything. Quality has to be right up there with quantity. So unlike many other mask manufacturers, Breathe is also building it's own in-house test facility. "We need air for some very sophisticated testing equipment going into a test room. This isn't required for producing masks, but we took it upon ourselves to raise the bar and to brand ourselves as being pretty much the only company in North America that actually produces in a clean room. We're hiring a biologist who will work with the teams to monitor masks randomly taken off the lines."

Saving lives and saving energy

Installing so much machinery in one go meant that decisions made now would have a huge impact on efficiency going forward. Breathe worked with Mearl's Machine Works in Kelowna, who were able to guide Wayne and his team through a lot of the planning and introduce them to BC Hydro's Self-serve Incentive Program (SIP). This is aimed at facilities using more than 500 megawatt-hours of electricity per year and wanting to upgrade compressed air systems and/or industrial lighting.

"Mearl's and BC Hydro made sure we're ahead of the curve. It was nice to have people that knew the ropes because that saved us from having to study up and know all this information. We don't want stuff to fail and they recommended certain types of pipe and compressors. We're using the best dryers and oil separators. We'll literally be scrubbing air. In fact, we could probably bottle air in here and sell it!"

The total cost of Breathe's project was $170K, supported by a BC Hydro SIP incentive of $24.2K, with projected energy savings of 67,000 kWh/yr.

Tips for growth

So with machinery now installed and production just about to start, what would Warren say to other businesses planning to embark on an ambitious expansion or new plant?

"Be prepared for lots of surprises or changes in the process as nothing goes to plan right away. You'll find all kinds of things you weren't expecting like building code requirements. Plus, in the current situation, we couldn't go to China and test or look at machinery. So make sure you allow enough time to commission all the equipment. We knew this and allocated funds for it."

Warren is also very appreciative of all the support Breathe has had: "There's a lot of proud Canadians going above and beyond because they want to be part of this particular project. We want to look after what we can in Canada. Not that we can't fulfill elsewhere, but most of our first orders are Canadian owners. If we had two more buildings operational, we still couldn't meet our orders. We're getting people calling and they want billions not millions."

There's still time to apply for our SIP promotion

If your business can identify the right kind of energy-efficient upgrades, our current SIP promotion can add up to a 25% bonus on top of the incentive amount, and potentially fund up to 100% of the project.

This means that with a $10K incentive, you'd now receive up to an additional $2.5K ($12.5K total incentive) if your completed project meets our cost-effectiveness tests.

Time is running out, but you still have until September 1, 2020 to get your incentive agreement in place. So contact us by email, or call the Business Helpdesk at 1 866 522 4713.

Get the latest COVID-19 advice for your business

Make sure your team and your business are benefitting from the latest B.C. Government advice on COVID-19, including their Support for Businesses information.

And of course, we're here to help. Reach out to your Key Account Manager or Regional Energy Manager if you have any questions or concerns.