Kamloops university's district energy plan reduces CO2

TRU is a slam dunk as a BC Hydro Clean Energy Champion

Part of a series on BC Hydro Clean Energy Champions: businesses, homes, and institutions – large and small – recognized for reducing their reliance on fossil fuels.

What do you do when you've already earned a reputation as one of Canada's most sustainability-minded universities? If you're Thompson Rivers University (TRU) in Kamloops, you double down.

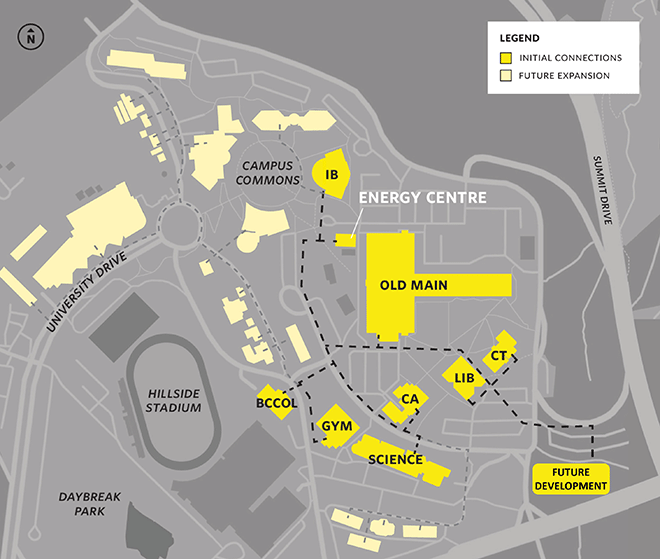

By 2025, a low-carbon district energy system of air-source and water-source heat pumps will provide heat and hot water to TRU's new school of management and eight existing academic buildings. Eventually, all but the smaller buildings on the campus will be hooked up to the system. The switch away from reliance on natural gas boilers in favour of clean electrification will reduce the school's GHG emissions by an estimated 100,000 tonnes over 30 years.

That's equivalent to the CO2 reduction benefits in planting a 4,000-acre forest, a tract 16 times the size of the TRU campus. And it's in keeping with TRU's reputation as a sustainability leader.

In 2018, TRU became the first post-secondary institution in Canada to earn a platinum sustainability rating through the Sustainability Tracking and Assessment Rating System (STARS), and they're still one of only 11 schools in the world with that rating. It's done this by going green in everything from the way buildings are built and designed, to transportation to the campus, to waste and water management.

"Sustainability is not something we do off the sides of our desks – it's something we do with intent," says Matt Milovick, TRU's VP of finance and administration. "We've been strategic about this. All the low hanging fruit, like changing light bulbs, is gone. All the easy stuff we've done. Now we have to get serious about reducing our GHGs."

In a partnership with Vancouver-based Creative Energy – a firm that specializes in district energy systems – TRU will pay for the system through rates paid to Creative Energy. Milovick says that even with $1.7 million in BC Hydro low carbon electrification program funding to take the sting out of project costs, payback on the massive project will be gradual. So the partnership with Creative Energy was vital to making it happen.

"They essentially became the utility provider, and we've just received government approval for them to do that," says Milovick. "It's a $25 million project, give or take. We're essentially taking on debt, and paying it back through the rates we pay over time to Creative Energy, which is financing most of the infrastructure."

Creative Energy is no stranger to district energy systems. For five decades, it has been using a central steam plant using high-efficiency gas boilers to provide heat to buildings in downtown Vancouver. And in 2021, it partnered with BC Hydro on a plan to partially electrify its steam generation to reduce GHG emissions by an estimated 25,000 tonnes per year.

Fifteen kilometres of pipes from Creative Energy's central Vancouver steam plant serve more than 210 buildings in downtown Vancouver, including BC Place Stadium, Rogers Arena, and Vancouver Public Library's central branch.

'There are certain things that we have societal responsibility to do'

TRU didn't arrive at the idea of a low-carbon district energy system overnight. It all started with a discussion about how a biomass boiler might make sense for an addition to TRU's technology and trades buildings.

But while biomass has worked for the likes of the University of B.C., TRU settled on an electric boiler that still allowed them to stop using natural gas as their primary source of heating and cooling in two buildings. Next up, TRU decided it would avoid natural gas for a big new building, the Chappell Family Building for Nursing and Population Health, that opened in September of 2020.

"We decided we weren't going have any natural gas connections in that building," says Milovick. "We used heat pumps instead, and then we were kind of hooked. We moved into discussions with Creative Energy for a low carbon district energy system, and that's where we are today."

Milovick has a history with heat pumps – the Ontario home he grew up was equipped with one way back in the 1980s. But as a numbers guy the math around long-term benefits of electrification just made sense. Rather than bear the costs down the road of replacing natural gas boilers in each campus building, it would bet big on heat pumps with the expectation that government pressure to reduce C02 emissions will increase as we near 2030.

"We know that somebody is going to dictate that we reduce our emissions at some point," he says. "So we'd rather be ahead of it. We're a progressive campus that's doing reasonably well financially. I think there are certain things that we have societal responsibility to do. And this would be one of those things."

Clean electricity leads to a customized system at TRU

When completed, TRU's new energy centre will house a series of air- and water-source heat pumps with a combined capacity equivalent to about 2,000 typically-sized heat pumps for single-family homes. The air-source heat pumps will draw heat from outside air – even in winter, at temperatures as low as -15°C – to heat water to a temperature between 40°C and 50°C. Because that's not hot enough for the legacy HVAC systems used in TRU's older buildings, which use radiators and coils to distribute heat to rooms, the water-source heat pumps will boost water temperatures to 72°C.

"The design of the district energy system was really driven by the vintage of buildings at TRU," says Diego Mandelbaum, Creative Energy's senior VP of development. "TRU started constructing these buildings back in the 1960s and 1970s, and HVAC systems were designed with high-temperature hot water, because they all had gas boilers. So we had to design for those constraints."

Once the district energy system is running, the role of gas boilers will be for backup heating only. Mandelbaum estimates that natural gas will provide less than 5% of the heating load. Cooling will continue to be provided by electric chillers in each building at TRU.

The big payoff in switching from fossil fuels is in the GHG reductions from using BC Hydro's clean power.

"I don't think this project would be viable without it," says Mandelbaum. "If you don't have a clean and economic source of low-carbon electricity, it's incredibly difficult, if not close to impossible, to decarbonise like this. So the backbone of this is the BC Yydro clean electricity grid that's also reasonably priced."

Mandelbaum says TRU's bottom line on the project will improve as the district energy system is extended beyond the campus to other nearby residences. Creative Energy is working with the City of Kamloops on what that will look like, with an initial agreement to link the system to the City's Tournament Capital Centre adjacent to TRU, a complex that includes a fieldhouse, indoor track, wellness centre, and Canada Games Aquatic Centre.

"Thompson Rivers isn't just decarbonising their own campus," says Mandelbaum. "As they expand [use of the district energy system] to local residential and other uses, rates will get better for everybody."

Related: